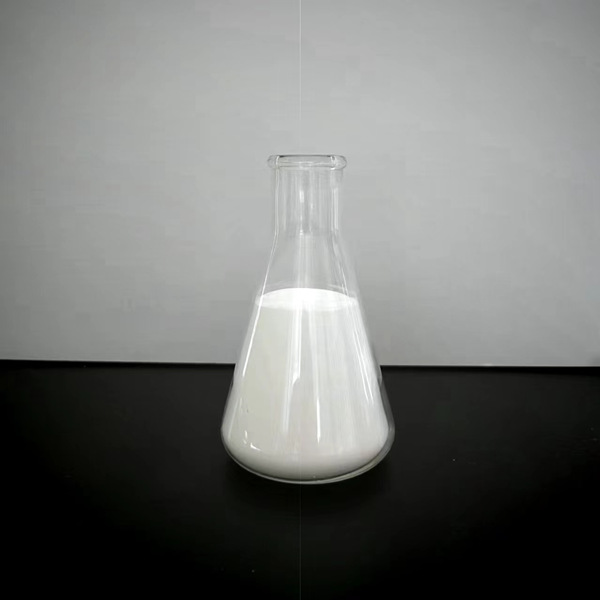

Vital wheat gluten

Vital wheat gluten is a kind of natural plant active protein product extracted from wheat flour by deep processing. Composed of a variety of amino acids, it is a nutrient-rich plant protein source. Because of its unique water absorption, rehydration, viscoelasticity, film formability, ductility, emulsification, it has been widely used in many industries such as meat food, bread baking, pet feed and aquatic feed.

Vital Wheat Gluten Production Process ———-

Operation steps:

· Wheat flour selection: Select wheat flour with high protein content and low ash content.

· Raw material inspection: Conduct inspection on wheat flour before storage, including appearance, odor, protein content, ash, impurity and moisture content and other indexes.

Equipment:

· Electronic Balance: Used for weighing and testing wheat flour.

· Moisture Analyzer: Used to test the moisture content of wheat flour.

· protein analyzer: used to determine the protein content of wheat flour.

Operation steps:

· Mixing: Mix wheat flour with appropriate amount of water to form a smooth dough.

· Washing: Wash the dough with water for several times to remove starch and soluble ingredients and retain gluten.

Equipment:

· Mixer: Used to mix wheat flour with water to form a uniform dough.

· Wash Tank: Used to wash the dough in water, usually with an agitation device to ensure adequate washing.

· Centrifugal separator: used to separate gluten from water and starch.

Operational steps:

· Gluten separation: Separation of gluten from water and starch by centrifugal separation or sieving.

· Dewatering: Dehydrate the wet gluten to reduce its moisture content.

Equipment:

· Centrifuge: for separating gluten from water.

· Press: Used for dewatering process, usually by screw press.

· Vacuum Dehydrator: Used to further reduce the moisture content of the gluten.

Operational steps:

· Drying: The dehydrated wet gluten is dried to obtain dry gluten flour.

Equipment:

· Hot Air Dryer: Drying of gluten meal by hot air with controlled temperature and humidity.

· Spray Dryer: Suitable for mass production, drying by spraying to form small particles.

· Drum dryers: Suitable for drying processes under specific conditions.

Operational steps:

· Grinding: The dried gluten mass is ground to a fine powder.

· Sieving: The ground gluten powder is sieved to ensure fineness and purity.

Equipment:

· Mill: Used to grind the dried gluten mass, usually with a high speed rotating mill or roller.

· Sifter: Used to sift the gluten meal to ensure uniformity of particles and fineness.

Procedure:

· Weighing and Packing: Weigh and pack according to predetermined specifications.

· Sealing and Storage: Seal the package to prevent moisture, pollution and oxidation.

Equipment:

· Automatic Packing Machine: Used for quantitative packaging to ensure accurate weight of each bag of gluten flour.

· Sealing Machine: Used to seal the bags to prevent the gluten flour from moisture and pollution.

Operation steps:

· Appearance Inspection: Check the color, smell and form of gluten flour.

· Physicochemical index test: Test protein content, moisture, ash, acidity, viscosity and fineness and other physical and chemical indexes.

· Microbiological Testing: Test for microbiological indicators such as colony count, coliform, mold and yeast.

· Safety Test: Test for heavy metals, pesticide residues and other harmful substances.

Equipment:

· Colorimeter: For detecting the color consistency of gluten flour.

· Gas Chromatograph: Used to detect acidity and other volatile components in gluten flour.

· Viscometer: for determining the viscosity of gluten flour.

· Microbiology Incubator: for cultivation and detection of microorganisms such as colony count, coliform and so on.

· Heavy metal detector: used to detect heavy metal content in gluten flour.

· Pesticide Residue Tester: Used for detecting pesticide residue in gluten flour.

Vital Wheat Gluten Applications ———-

– Bread and Pastry Making

Enhancement of gluten structure: Gluten powder increases the elasticity and ductility of the dough, helping bread and pastry to expand better during baking and enhancing the volume and texture of the bread.

Improves water retention: Increases the water retention of the dough, making the product softer and moister after baking.

– Pasta and Spaghetti

Improved texture: Enhances the strength and elasticity of the dough so that noodles and pasta are less likely to break during cooking and have a chewier texture.

– Vegetarian products

Vegetarian meat preparation: Gluten powder can be used to prepare vegetarian meats (e.g. vegetarian chicken, vegetarian steak, etc.), where its high protein content and fibrous texture mimic the taste and structure of meat.

– Frozen foods

Improvement of texture and water retention: In frozen foods (e.g. dumplings, ravioli), gluten powder improves the elasticity and water retention of the dough and prevents the texture from deteriorating after thawing.

– Baking mixes

Added to baking premixes: Enhances gluten content and improves the texture and stability of the final product.

– Animal feed

High protein additive: Gluten powder can be added to animal feed as a high protein source to enhance the nutritional value of the feed.

Enhance feed adhesion: Improve the adhesion of feed particles, making it easier to mold and preserve the feed.

– Pet food

High-protein ingredient: Used to make high-protein pet food, such as cat food and dog food, to provide the high-quality protein needed by pets.

– Paper and textiles

Binder: Gluten powder can be used as a natural binder in the production of paper and textiles, providing good bonding properties and environmentally friendly characteristics.

– Bioplastics

Environmentally friendly material: Used to prepare biodegradable plastics to reduce environmental pollution.

– Cosmetics and personal care products

Skin care additives: used as moisturizing and film-forming agents in cosmetics to increase product stability and sense of use.

– Protein supplements

High Protein Powder: Used in the preparation of protein supplements to provide high quality protein required by the human body, suitable for fitness people and people with high protein demand.

– Pharmaceutical Excipients

Preparation Ingredients: Used as excipients and stabilizers in pharmaceutical preparations to help shape and stabilize the drug.