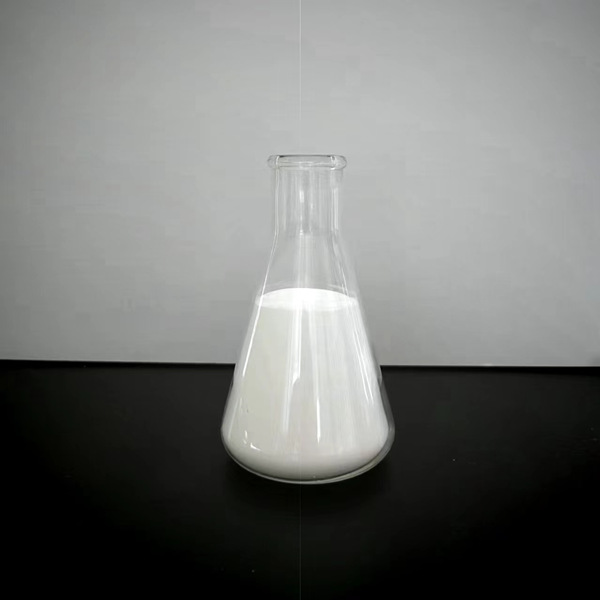

Udon noodle

Pack size: 200g/bag

Shelf life: 12 Months

Ingredients: Wheat Flour, Water, Additives(Acetate Starch,Lactic Acid, Sodium Lactate), Salt.

Storage Conditions:Store in a cool and dry place at room temperature. Keep away from light.

Udon Noodle Raw Materials ———-——-

– Imported Australian wheat flour + high-quality wheat flour from Jiaodong Peninsula :

(1) High protein content: Australian wheat is famous for its high protein content, which makes the noodles more chewy and elastic.

(2) Low ash content: The low ash content makes the flour white in color, which gives the noodles a better visual effect after cooking.

(3) Consistent quality: Australian wheat cultivation and processing technology is very advanced, ensuring consistent quality in every batch of flour.

(4) Natural and non-polluting: Australia’s pure agricultural environment ensures that the wheat is free of pollution and residue and meets international food safety standards.

– Water: Pure water is used to ensure the hygiene and safety of the noodles.

– Tapioca Starch: Increase the elasticity and toughness of the noodles, making them smoother in texture.

– Sodium Alginate: Natural seaweed extract, which helps to shape the noodles and keep them moist.

– Lactic Acid: Lactic acid produced by natural fermentation regulates the pH of the dough and improves the texture of the noodles.

– Sodium Lactate: acts as a humectant and preservative to extend the shelf life of the noodles.

– Salt: Enhances the flavor of the noodles and helps the gluten formation of the dough.

Udon Noodle Production Process ——-———

1. Ratio of raw materials

– Selected raw materials: including imported wheat flour from Australia, high quality wheat flour from Jiaodong Peninsula, purified water, acetate starch, sodium alginate, lactic acid, sodium lactate and salt.

– Precise Measurement: Each raw material is weighed according to scientific ratios to ensure consistent quality from batch to batch.

– Homogeneous Mixing: Large industrial mixers are used to mix all raw materials to ensure a homogeneous mixture.

2. Mixing

– Into the mixing machine: The homogeneous mixture of raw materials is put into the mixing machine.

– Mixing process: The mixing machine mixes the raw materials into a smooth and elastic dough through powerful mixing and kneading.

– Moisture control: During the mixing process, water is added to ensure that the moisture and viscosity of the dough is optimized.

3. Wake

– Resting the Dough: The dough is rested in the dough room for a period of time, usually 30 minutes to 1 hour.

– Gluten formation: Through resting, the gluten network in the dough is gradually formed, which improves the toughness and ductility of the dough.

– Temperature control: The temperature and humidity in the dough room are controlled to ensure the fermentation and texture of the dough.

4. Pressing

– Into the press: Put the dough into the press.

– Pressing: The dough is pressed by the press to form a uniform sheet, controlling the thickness of the sheet within the set range.

– Multiple pressing: Press the dough several times to make the dough sheet more even and smooth, and the thickness is consistent.

5. Cutting

– Cutting machine: Feed the noodle sheet into the cutting machine and cut it into 4.5mm wide round or rectangle noodle according to the specification. Length control: During the cutting process, the noodle sheet will be cut into a uniform thickness.

– Length control: During the cutting process, the length of the noodles is strictly controlled to ensure that the size of each package of noodles is consistent.

– Anti-sticking treatment: The cut noodles are treated with anti-sticking treatment to prevent the noodles from sticking to each other.

6. Steaming

– Put into steamer: Put the cut noodles into the steamer.

– Precise Cooking: The cooking time and temperature are precisely controlled to ensure that the noodles are fully cooked.

– Retain elasticity: During the steaming process, the texture of the noodles is strictly monitored to ensure optimal elasticity and flavor.

7. Cooling

– Rapid Cooling: Cool the noodles quickly after steaming to prevent overcooking.

– Cooling Equipment: Specialized cooling equipment is used to quickly reduce the temperature of the noodles to below room temperature.

– Maintaining texture: The rapid cooling process ensures that the noodles retain their elasticity and texture.

8. Package

– Quantitative Package: The cooled noodles are quantitatively packaged according to the set specifications (200g per bag).

– Sealing: The bags are made of food-grade material and sealed to ensure the hygiene and freshness of the noodles.

– Quality Inspection: Final quality inspection is carried out before packing to ensure that each pack of noodles meets the company’s quality standards.

– Storage and Transportation: The packaged noodles are put into the storage room, ready for transportation and sale, and the storage environment is controlled in the appropriate temperature and humidity range.

Udon Noodle Quality Control ——–———-

– At every stage of production, we have strict quality control measures in place to ensure that the noodles are hygienic, safe and consistent in taste.

– We conduct regular tests on microbiological and physicochemical indicators to ensure that our products comply with international food safety standards.